Replaced our stream boiler

(video at bottom)The steam boiler in my house was very old and and over time the cast iron rusted and for years

I would flush out the system in the beginning and end of the heating season. One night we heard a load bang and a hissing

sound coming from the boiler.

You will see in the images the sections cracked and I even tried to use some 2-part epoxy to see if it was hold for the night

but realized the cracks were not only on the exterior but on the interior also. So I called the supply house and ordered a

new steam boiler and had it delivered to the house on a pallet. While we were waiting for the boiler to be delivered we had

time to start dismantling the existing steam boiler. Each section was 2-300lbs so we had to break the sections up into smaller

pieces due to the shear weight. We decided to use dumpster in a bad for disposal. We were able to stage the bag in our walkway

and once filled waste management came with a hydraulic arm and reached over the fence and picked it up into the truck.

We then cleaned up the basement area and purchased 6 patio blocks from home depot. I used some self leveling cement and layed

the blocks 2 long by 3 wide. I then painted the area to seal the cement and start with a clean slate with the new boiler.

The entire new boiler weighed about the same as a single section of the previous boiler. Keep in mind the previous boiler had 5

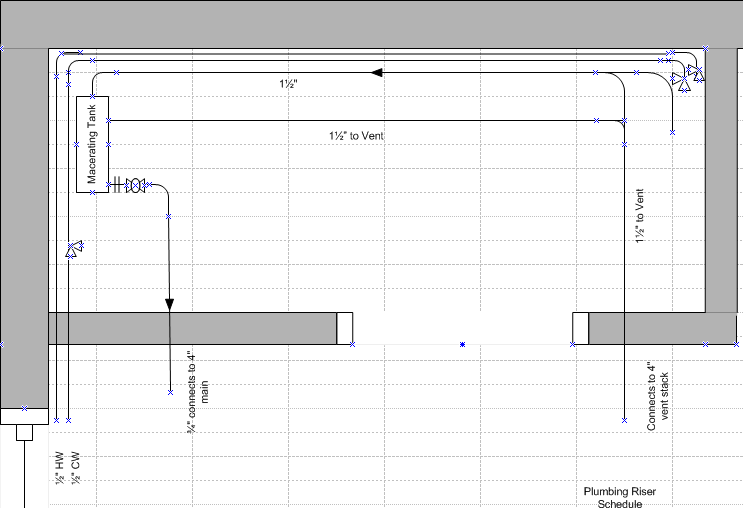

or 6 sections. I started to take some measurements for piping and the main headers as seen in the images was 2" diameter. The

gas line supply for the new boiler was 1/2" diameter where as the old boiler was 1" so we just reduced it to suit our needs.

Since I didn't have a commercial threading maching I just took the measurements to the supply house and got what I needed. A few

trips back and forth and I eventually got everything I needed.

We had to also get some 6" smoke pipe which is silver in color you will see in the video images.

After assembly we filled the boiler a few inches above the recommended fill level and removed the cleanout plug that we had installed

in the tee fitting and fired up the boiler. We had to boil out the oil & grease from the pipes and the boiler. We had to be careful

not to over heat and cause steam. As the water started to boil the oil & grease float on the water and evacuate through the

cleanout we had open. We repeated this process a few times to make sure we got it all. Skipping this step will cause loud banging

and can damage the boiler and piping.

So the new boiler was so efficient that our bill for that entire winter was less then one month from the previous winter. The entire

job cost around $2400 with the materials and disposal. This type of job is not suited for many but is an informational video from my

experience. If you decide take this type of job on then make sure to visit the building department to pull the permits.

If you enjoy the video subscribe for updates.

More videos will come as there comes time to make them.